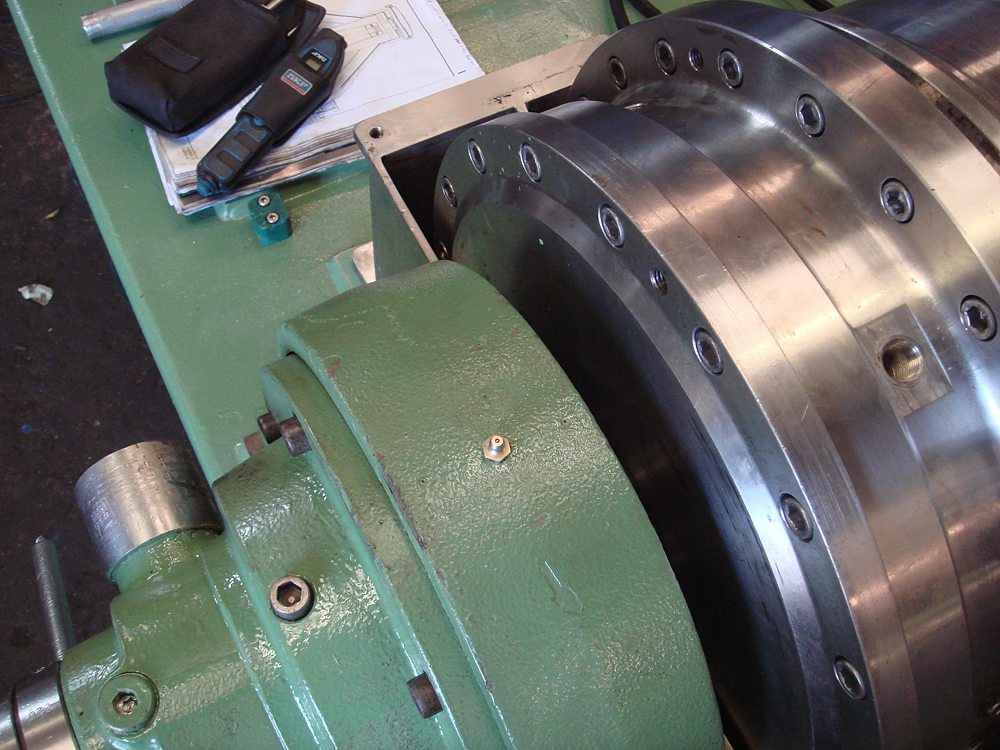

Centri-Force is a leading independent service provider in the UK, providing after care for all makes of vertical disc stack centrifuges and also horizontal decanter centrifuges. It’s this expertise that makes the difference. We’ve been doing it for 40 years.