Frame: Painted Carbon Steel, or 304 Stainless Steel

Plates: Stainless: 304 and 304L stainless; 316 and 316L stainless

Exotics: Titanium, Titanium-Palladium, SMO-254, Incoloy 825, Nickel, Hastelloy, Monel, Inconel, Tantalum

Gaskets: Nitrile, EPDM, Viton, Compressed Fiber, Glued or Clip-on designs

Connections: FPT, MPT, Studded, Flanged, Tri-Clamp, others

Capacities: 0.5 GPM to 8800 GPM

Codes: ASME

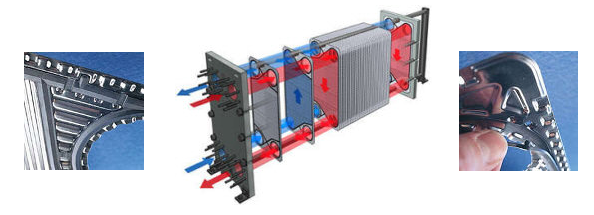

API Heat Transfer’s line of Schmidt-Bretten Plate Heat Exchangers incorporates superior design features to ensure long term customer satisfaction.

- Highest quality gaskets precisely fit the plate grooves for positive sealing and ease of maintenance. Superior clip-on gasket design ensures proper fit during closing of the unit.

- Double sealing design prevents the possibility of mixing the two process fluids. Leak detect feature ensures any leakage is to the atmosphere.

- Zinc coated hardware provides long life.

- All plate pack tightening is done from the fixed pressure plate to eliminate any stud interference.

- All bolted construction for easier service.

- Low volumetric fluid hold-up provides quicker response to heating and cooling demands, while reducing costs for more expensive process fluids.

- Readily expanded for greater capacities, or totally new applications