Centri-Force is a quality-based company, with accreditations in ISO 9001, ISO 14001, ISO 45001 UVDB Achilles Verify and Safe Contractor

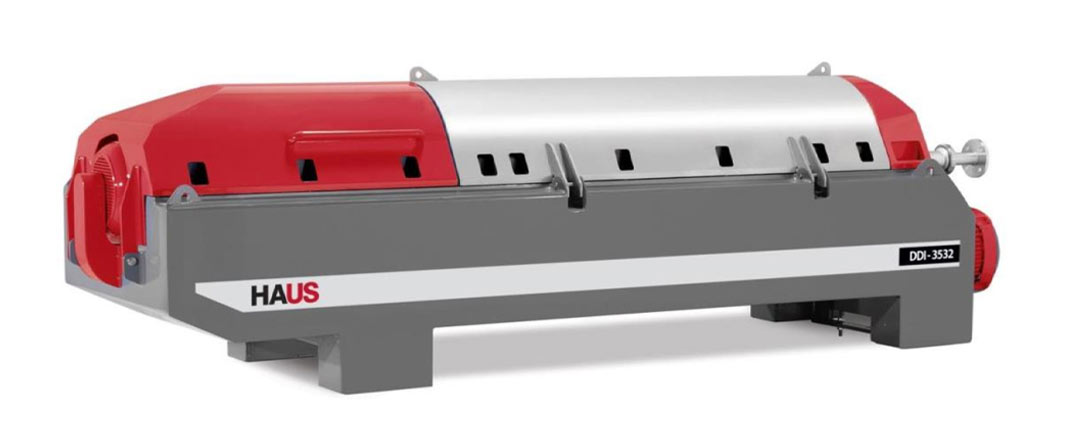

We are pleased to offer the full range of decanter centrifuges from HAUS Centrifuge Technologies. Fully refurbished centrifuges are also available from stock.

We offer new HAUS High Speed Disc Stack Separators, Purifiers, Clarifiers and Concentrators. Refurbished separators are available from stock.

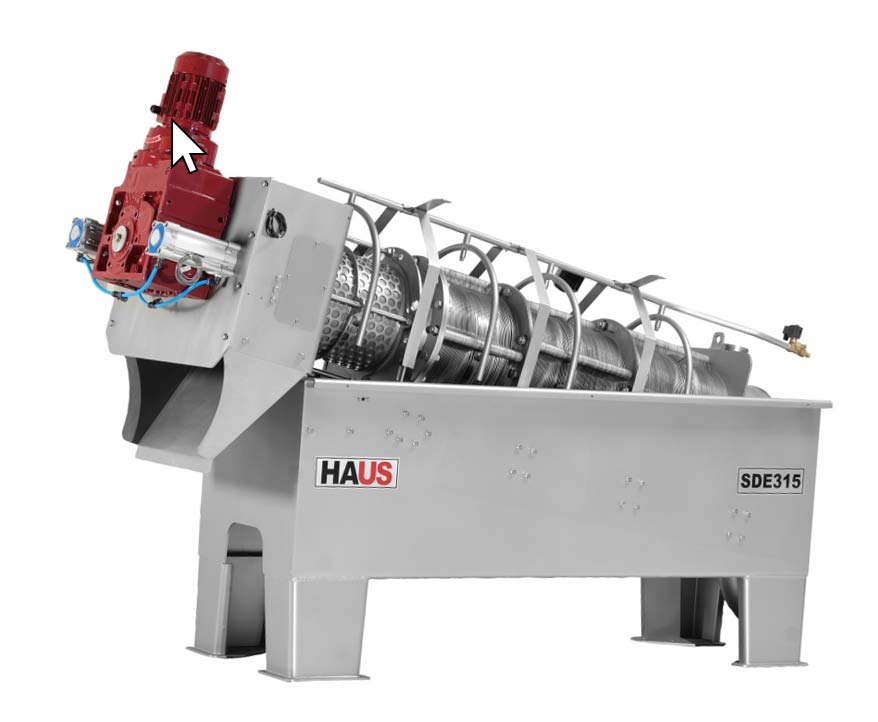

We are pleased offer new HAUS advanced Screw Presses for dewatering municipal and industrial waste water.

We offer advanced Plate Heat Exchanger technology from API Schmidt Bretton in Germany.

We are pleased to offer technically advanced Shell and Tube Heat Exchangers from Sacome in Spain.